Stainless steel is a a type of steel which enjoys corrosion resistance, high ductivity, atrractive appearance and low maintenance. With different types of surface processing, like hairline surface, mirror surface, our stainless steel products satisfy different decorative usages.

MOQ :

10TPayment :

T/T, L/C at sightProduct Origin :

ChinaShipping Port :

Shenzhen/GuangzhouStainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's resistance to corrosion results from the chromium, which forms a passive film that can protect the material and self-heal in the presence of oxygen.

PRODUCT CHARACTERISTICS & APPLICATIONS

|

Series |

Grade |

Characteristics |

Applications |

|

|

Austenite |

Basic |

SUS304 |

Widely used, corrosion resistant, heat resistant, good mechanical properties in low temperature, no heat treatment hardening, weak magnetism. |

Home kitchen utensils, chemical industry, medical apparatus, building material and decoration |

|

SUS304L |

Better intergranular corrosion resistance, can be heat treated after welding. |

Petroleum equipment, chemical equipment, building material, heat resistant parts and the parts are difficult to heat treat |

||

|

High Tensile Strength |

SUS301 |

Lower content of Cr and Ni than 304 grade. It’s strength, hardness and magnetism can be increased by cold working. |

Trains, air crafts, vehicles, springs |

|

|

SUS301L* |

Improving intergranular corrosion resistance by decreasing content and increasing N content from 301 grade. |

Frame and crust parts of train |

||

|

Deep Drawing |

SUS304Cu |

Better formability than 304 grade by addition of Cu, suitable for deep drawing. |

Domestic appliances |

|

|

SUS304Ni8.5 |

Better formability than 304 grade by increasing Ni content, suitable for deep drawing. |

Domestic appliances |

||

|

SUS304Ni9 |

Better formability than 304 grade by increasing Ni content, suitable for deep drawing. |

Domestic appliances |

||

|

High Corrosion Resistance |

SUS316* |

Better corrosion resistance than 304 grade in sea water and other corrosive solutions, higher heat-resistance, good cold work hardening performance, no magnetism . |

Chemical industry, food processing equipments, coastal installations. |

|

|

SUS316L |

Compared with SUS316, this grade has better intergranular corrosion resistance and lower heat-resistance, no magnetism |

Chemical industry and food processing equipments used in severe corrosive condition, coastal installations used |

||

|

SUS321 |

Intergranular corrosion resistant, heat resistant, good formability and weldability, anti-oxidizing in high temperature. |

Jet engine parts, heat exchanger, boiler cover, chemical devices |

||

|

Ferrite |

Basic |

SUS430 |

Typical ferritic stainless steel grade, low thermal expansibility, good formability and antioxygenic property. |

Heat-resistant utensils, combustion devices, domestic appliance, kitchen utensils category, building decorating material |

|

Weldable and Corrosion Resistant

|

SUH409L |

Good formability and weldability, antioxygenic property in high temperature. |

Exhaust system of automobiles |

|

|

SUS436L* |

Good corrosion resistance, formability and weldability. Corrosion resistant to condensates in exhaust piping of automobiles. |

Automobile exhaust piping, boiler |

||

|

SUS444* |

Good corrosion resistance, formability and weldability. Compared with 316L, this grade has better stress corrosion resistance and spot corrosion resistance. |

Water heater, water tank, automobile exhaust piping |

||

|

Martenslte |

Basic |

SUS420J2* |

High post-quenching strength, suitable for wearable parts. |

Knife, pipe nozzles, valves, metal rules and cooking utensils. |

Notes: * refers to none-conventional products, please contact us for details if you have further needs.

PRODUCE SPECIFICATION(For reference)

Table 1: Available Width (Unit: mm)

|

No. |

Width Thickness |

650≤w<850 |

850≤w<950 |

950≤w<1050 |

1050≤w<1150 |

1150≤w<1250 |

1250≤w<1320 |

|

1 |

0.2≤t<0.3 |

|

|

|

|

|

|

|

2 |

0.3≤t<0.4 |

|

|

|

|

|

|

|

3 |

0.4≤t<0.5 |

|

|

|

|

|

|

|

4 |

0.5≤t<0.7 |

|

|

|

|

|

|

|

5 |

0.7≤t<0.9 |

|

|

|

|

|

|

|

6 |

0.9≤t<1.1 |

|

|

|

|

|

|

|

7 |

1.1≤t<1.3 |

|

|

|

|

|

|

|

8 |

1.3≤t<1.7 |

|

|

|

|

|

|

|

9 |

1.7≤t<2.0 |

|

|

|

|

|

|

|

10 |

2.0≤t≤3.0 |

|

|

|

|

|

|

|

11 |

3.0<t≤4.0 |

|

|

|

|

|

|

Notes: green coverage: available range; yellow coverage: negotiable range; white coverage: Unavailable range.

Table 2: Available Surface (Unit: mm)

|

No. |

Width Thickness |

300 Series |

400 Series |

||||||||||||||

|

No.1 |

2D |

2B |

No.3 |

No.4 |

HL |

BA |

RS |

No.1 |

2D |

2B |

No.3 |

No.4 |

HL |

BA |

RS |

||

|

1 |

0.20≤t<0.25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

0.25≤t<0.30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

0.30≤t<0.35 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

0.35≤t<1.20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

1.20≤t<1.50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

1.50≤t<2.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

2.00≤t<3.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

t=3.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

3.00<t≤4.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

4.00<t≤6.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Notes: green coverage: available range; yellow coverage: negotiable range; white coverage: Unavailable range.

STEEL GRADE, CHEMICAL COMPOSITION & MECHANICAL PROPERTY

The product are in accordance to the latest revision of Chinese national standard (GB/T3280), Japanese industrial standard (JIS G4305), American of testing materials (AS TM A240) and European norm(EN 10088-2), at customer’s option.

Table 1(a): Steel Grade and Chemical Composition(For reference)

|

Series |

Standard and Steel Designation |

Main Chemical Composition |

|||||||||||

|

JIS |

GB |

ASTM |

EN |

C Max |

Si Max |

Mn Max |

P Max |

S Max |

Ni |

Cr |

Others |

||

|

Austenite |

Basic |

SUS304 |

0Cr18Ni9 |

S30400 |

1.4301 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

8.00-10.5 |

18.00-20.00 |

- |

|

SUS304L |

00Cr19Ni10 |

S30403 |

1.4307 |

0.030 |

1.00 |

2.00 |

0.045 |

0.030 |

9.00-13.00 |

18.00-20.00 |

- |

||

|

High Tensile Strength |

SUS301 |

1Cr17Ni7 |

S30100 |

1.4310 |

0.15 |

1.00 |

2.00 |

0.045 |

0.030 |

6.00-8.00 |

16.00-18.00 |

- |

|

|

301B* |

1Cr17Ni7 |

S30100 |

1.4310 |

0.095-0.135 |

0.50-0.80 |

0.60-0.90 |

0.035 |

0.030 |

6.55-6.85 |

16.25-16.75 |

Mo:0.40; Cu:0.40; N:0.045 |

||

|

301S* |

1Cr17Ni7 |

S30100 |

1.4310 |

0.110-0.145 |

0.30-0.60 |

1.60-1.90 |

0.035 |

0.030 |

6.10-6.40 |

16.30-16.90 |

Mo:0.40; Cu:0.40; N:0.04-0.07 |

||

|

SUS301L* |

- |

S30103 |

1.4318 |

0.030 |

1.00 |

2.00 |

0.045 |

0.030 |

6.00-8.00 |

16.00-18.00 |

N:0.20 |

||

|

Deep Drawing |

SUS304(Ni8.5) |

0Cr18Ni9 |

S30400 |

1.4301 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

8.50-10.5 |

18.00-20.00 |

- |

|

|

SUS304(Ni9) |

0Cr18Ni9 |

S30400 |

1.4301 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

9.00-10.5 |

18.00-20.00 |

- |

||

|

SUS304Cu |

0Cr18Ni9 |

S30400 |

1.4301 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

8.00-10.5 |

18.00-20.00 |

Cu:0.70-1.30 |

||

|

High Corrosion Resistance |

SUS316* |

0Cr17Ni12Mo2 |

S31600 |

1.4401 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

10.0-14.0 |

16.00-18.00 |

Mo:2.00-3.00 |

|

|

SUS316L |

00Cr17Ni14Mo2 |

|

|

0.030 |

1.00 |

2.00 |

0.045 |

0.030 |

12.00-15.00 |

16.00-18.00 |

Mo:2.00-3.00 |

||

|

316L(ASTM) |

- |

S31603 |

|

0.030 |

0.75 |

2.00 |

0.045 |

0.030 |

10.0-14.0 |

16.00-18.00 |

Mo:2.00-3.00 |

||

|

SUS321 |

0Cr18Ni10Ti |

S32100 |

1.4541 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

9.00-13.00 |

17.00-19.00 |

Ti:5*C% |

||

|

Ferrite |

Basic |

SUS430 |

1Cr17 |

S43000 |

1.4016 |

0.12 |

0.75 |

1.00 |

0.040 |

0.030 |

- |

16.00-18.00 |

- |

|

Heat Resistant and Anti-oxidizing |

SUH409L |

- |

S40910 |

1.4512 |

0.030 |

1.00 |

1.00 |

0.040 |

0.030 |

- |

10.50-11.75 |

Ti:6*C%-0.75 |

|

|

SUS410L |

00Cr12 |

S41003 |

1.4003 |

0.030 |

1.00 |

1.00 |

0.040 |

0.030 |

- |

11.00-13.50 |

- |

||

|

Weldable and Corrosion Resistant

|

SUS436L* |

00Cr17Mo |

|

|

0.025 |

1.00 |

1.00 |

0.040 |

0.030 |

- |

16.00-19.00 |

Mo:0.75-1.50 Ti,Nb,Zr:8*(C%+N%)-0.80 |

|

|

439(ASTM) |

00Cr17 |

S43035 |

1.4510 |

0.030 |

1.00 |

1.00 |

0.040 |

0.030 |

0.50 |

17.00-19.00 |

Ti:[0.20+4*(C+N)]~1.10 Al:0.15; N:0.030 |

||

|

SUS444* |

00Cr18Mo2 |

S44400 |

1.4521 |

0.025 |

1.00 |

1.00 |

0.040 |

0.030 |

- |

17.00-20.00 |

Mo:1.75-2.50 Ti,Nb,Zr:8*(C%+N%)-0.80 |

||

|

Martenslte |

Basic |

SUS420J2* |

3Cr13 |

|

1.4028 |

0.26-0.40 |

1.00 |

1.00 |

0.040 |

0.030 |

- |

12.00-14.00 |

- |

Table 1(b): Steel Grade and Mechanical Property (For reference)

|

Series |

Standard and Steel Designation |

Main Mechanical Property (Solution Treatment or Annealing) |

||||||||||

|

JIS |

GB |

ASTM |

EN |

Yield Strength N/mm² |

Tensile Strength N/mm² |

Elongation % |

Hardness |

Bending |

||||

|

HV |

HRB |

Bending Angle |

Bending Radius |

|||||||||

|

Austenite |

Basic |

SUS304 |

0Cr18Ni9 |

S30400 |

1.4301 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

- |

- |

|

SUS304L |

00Cr19Ni10 |

S30403 |

1.4307 |

≥175 |

≥480 |

≥40 |

≤200 |

≤90 |

|

|

||

|

High Tensile Strength |

SUS301 |

1Cr17Ni7 |

S30100 |

1.4310 |

≥205 |

≥520 |

≥40 |

≤218 |

≤95 |

- |

- |

|

|

301B* |

1Cr17Ni7 |

S30100 |

1.4310 |

≥205 |

≥520 |

≥40 |

≤218 |

≤95 |

- |

- |

||

|

301S* |

1Cr17Ni7 |

S30100 |

1.4310 |

≥205 |

≥520 |

≥40 |

≤218 |

≤95 |

- |

- |

||

|

SUS301L* |

- |

S30103 |

1.4318 |

≥215 |

≥550 |

≥45 |

≤218 |

≤95 |

- |

- |

||

|

Deep Drawing |

SUS304(Ni8.5) |

0Cr18Ni9 |

S30400 |

1.4301 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

- |

- |

|

|

SUS304(Ni9) |

0Cr18Ni9 |

S30400 |

1.4301 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

|

|

||

|

SUS304Cu |

0Cr18Ni9 |

S30400 |

1.4301 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

|

|

||

|

High Corrosion Resistance |

SUS316* |

0Cr17Ni12Mo2 |

S31600 |

1.4401 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

- |

- |

|

|

SUS316L |

00Cr17Ni14Mo2 |

|

|

≥175 |

≥480 |

≥40 |

≤200 |

≤90 |

- |

- |

||

|

316L(ASTM) |

- |

S31603 |

|

≥170 |

≥485 |

≥40 |

≤200 |

≤95 |

- |

- |

||

|

SUS321 |

0Cr18Ni10Ti |

S32100 |

1.4541 |

≥205 |

≥520 |

≥40 |

≤200 |

≤90 |

- |

- |

||

|

Ferrite |

Basic |

SUS430 |

1Cr17 |

S43000 |

1.4016 |

≥205 |

≥420 |

≥22 |

≤200 |

≤88 |

180° |

1.0 Time of Thickness |

|

Heat Resistant and Anti-oxidizing |

SUH409L |

- |

S40910 |

1.4512 |

≥175 |

≥360 |

≥25 |

≤175 |

≤80 |

180° |

0.5 Time of Thickness |

|

|

SUS410L |

00Cr12 |

S41003 |

1.4003 |

≥195 |

≥360 |

≥22 |

≤200 |

≤88 |

180° |

1.0 Time of Thickness |

||

|

Weldable and Corrosion Resistant

|

SUS436L* |

00Cr17Mo |

|

|

≥245 |

≥410 |

≥20 |

≤230 |

≤96 |

180° |

1.0 Time of Thickness |

|

|

439(ASTM) |

00Cr17 |

S43035 |

1.4510 |

≥205 |

≥415 |

≥22 |

≤200 |

≤89 |

180° |

1.0 Time of Thickness |

||

|

SUS444* |

00Cr18Mo2 |

S44400 |

1.4521 |

≥245 |

≥410 |

≥20 |

≤230 |

≤96 |

180° |

1.0 Time of Thickness |

||

|

Martenslte |

Basic |

SUS420J2* |

3Cr13 |

|

1.4028 |

≥225 |

≥540 |

≥18 |

≤247 |

≤99 |

- |

- |

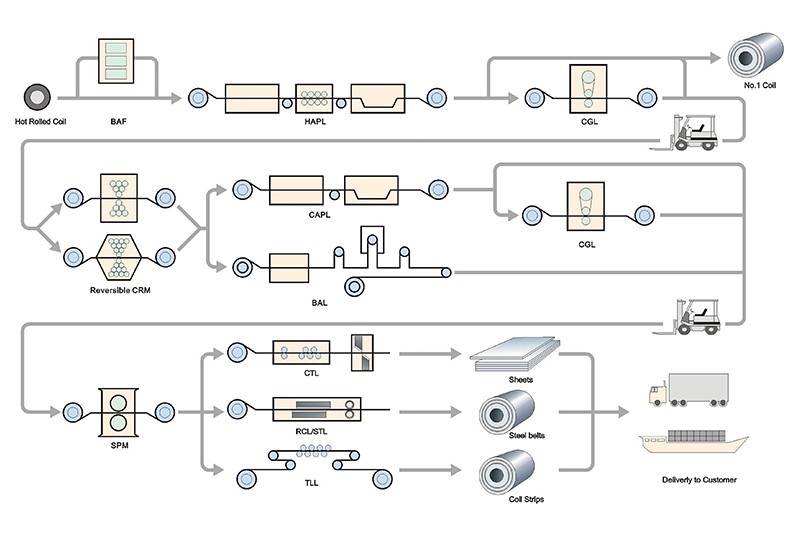

Production Process

|

Application

|

|

|

|

Packing

|

We will contact you as soon as possible